Page 10 - IFR_Book_Sample-2020

P. 10

IFR-Chapter-2-V10-BAK_Basic Master Frame.qxd 12/19/2019 4:13 PM Page 11

Chapter 2 - Your Flight Instruments: Behind the Panel 2-11

Understanding the Airplane’s Gust/Stress Envelope

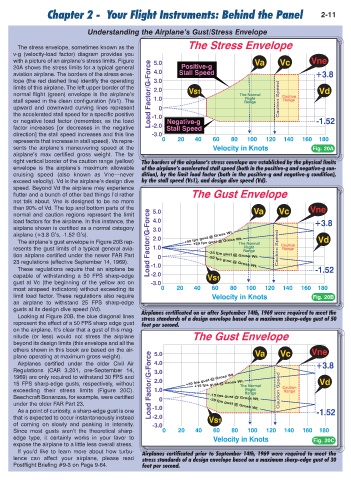

The stress envelope, sometimes known as the

v-g (velocity-load factor) diagram provides you

with a picture of an airplane’s stress limits. Figure

20A shows the stress limits for a typical general

aviation airplane. The borders of the stress enve-

lope (the red dashed line) identify the operating

limits of this airplane. The left upper border of the

normal flight (green) envelope is the airplane’s

stall speed in the clean configuration (Vs1). The

upward and downward curving lines represent

the accelerated stall speed for a specific positive

or negative load factor (remember, as the load

factor increases [or decreases in the negative

direction] the stall speed increases and this line

represents that increase in stall speed). Va repre-

sents the airplane’s maneuvering speed at the Fig. 20A

airplane’s max certified gross weight. The far

right vertical border of the caution range (yellow) The borders of the airplane’s stress envelope are established by the physical limits

envelope is the airplane’s maximum allowable of the airplane’s accelerated stall speed (both in the positive-g and negative-g con-

cruising speed (also known as Vne—never dition), by the limit load factor (both in the positive-g and negative-g condition),

exceed velocity). Vd is the airplane’s design dive by the stall speed (Vs1), and design dive speed (Vd).

speed. Beyond Vd the airplane may experience

flutter and a bunch of other bad things I’d rather

not talk about. Vne is designed to be no more

than 90% of Vd. The top and bottom parts of the

normal and caution regions represent the limit

load factors for the airplane. In this instance, the

airplane shown is certified as a normal category

airplane (+3.8 G’s, -1.52 G’s).

The airplane’s gust envelope in Figure 20B rep-

resents the gust limits of a typical general avia-

tion airplane certified under the newer FAR Part

23 regulations (effective September 14, 1969).

These regulations require that an airplane be

capable of withstanding a 50 FPS sharp-edge

gust at Vc (the beginning of the yellow arc on

most airspeed indicators) without exceeding its

limit load factor. These regulations also require Fig. 20B

an airplane to withstand 25 FPS sharp-edge

gusts at its design dive speed (Vd).

Airplanes certificated on or after September 14th, 1969 were required to meet the

Looking at Figure 20B, the blue diagonal lines stress standards of a design envelope based on a maximum sharp-edge gust of 50

represent the effect of a 50 FPS sharp edge gust feet per second.

on the airplane. It’s clear that a gust of this mag-

nitude (or less) would not stress the airplane

beyond its design limits (this envelope and all the

others shown in this book are based on the air-

plane operating at maximum gross weight).

Airplanes certified under the older Civil Air

Regulations (CAR 3.201, pre-September 14,

1969) are only required to withstand 30 FPS and

15 FPS sharp-edge gusts, respectively, without

exceeding their stress limits (Figure 20C).

Beechcraft Bonanzas, for example, were certified

under the older FAR Part 23.

As a point of curiosity, a sharp-edge gust is one

that is expected to occur instantaneously instead

of coming on slowly and peaking in intensity.

Since most gusts aren’t the theoretical sharp-

edge type, it certainly works in your favor to Fig. 20C

expose the airplane to a little less overall stress.

If you’d like to learn more about how turbu- Airplanes certificated prior to September 14th, 1969 were required to meet the

lence can affect your airplane, please read stress standards of a design envelope based on a maximum sharp-edge gust of 30

Postflight Briefing #9-3 on Page 9-64. feet per second.